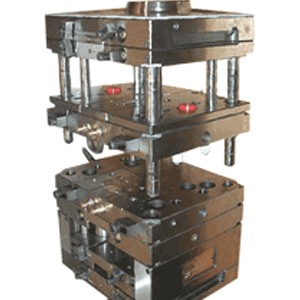

CPIM – a Titoma Group member, is a Western-managed project management firm that specializes in

molds and complex plastic assemblies. We offer our customers a significant cost reduction

(often > 50%) both on injection molds and the production of custom plastic assemblies.

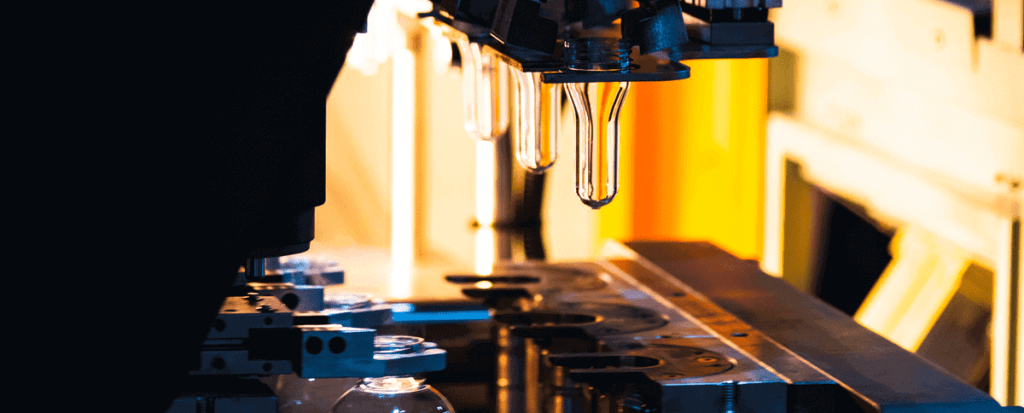

Most everybody knows that plastic molds from China are cheap, but there are also plenty of horror stories in the industry. If mold making in China goes wrong, it tends to go wrong in quite a big way; it can break a company.

We have many years of experience in the injection molding service business and know very well all customers’ concerns.

Think of our plastic injection molding services as risk insurance: We take away all the risks and headaches that you will sooner or later run into when trying to work with Chinese plastic injection molding manufacturers directly.

Over 20 years we’ve carefully selected, tested, and work countless times with specific plastic injection mold makers; we’ve reached a level where we can confidently and consistently follow a plastic injection molding process that works.

We’re not a company that will simply forward customer communications to a plastic injection molding company in say, Shenzhen China.

You’d be surprised at the number of companies out there that get a mold done like this; some sales managers will take a western company’s money and then just forward emails to a custom plastic injection molding manufacturer in China; they’ll outline some plastic injection molds characteristics to be produced and have a factory produce something.

Needless to say that molds produced this way won’t meet the levels of quality you’re expecting.

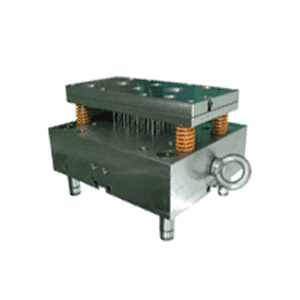

A lot of money goes into mold design and manufacturing; the whole process requires a lot of attention to ensure molds manufacturers get the project right; when it comes to plastic injection molds there’s no place for companies to make a mistake.

For a company, starting a plastic injection mold design and manufacturing project over, after failure, is not an option, the cost of this part of the product development process alone might be too much to bear.

Many companies never make it to the market, not because of supplier issues or market downturns; they simply go out of business because they were never able to get their plastic injection molds right and ran out of money before they could produce a good quality mold.

China plastic injection molding is a complex process, too complex to try to do it in-house; it needs to be outsourced to an expert company, and follow up the process thoroughly.

That’s why our Western management team and engineers are permanently located in Taiwan and China; they have an accumulated 70 years of experience in injection molding.

They oversee every step of the factory molding manufacturing service to make sure the customers get the injection molding service they paid for.

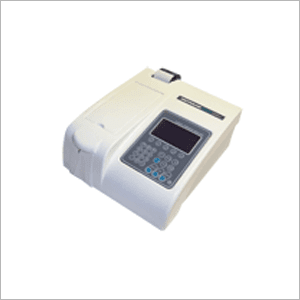

The Titoma Group provides a full complement of quality CAD services, including modeling of new products and 2D to 3D conversion. We also offer product engineering services ranging from design for China manufacturing to reverse and value engineering..

Design and manufacturing are the core of our business, we provide our customers with a full manufacturing service that goes beyond mold making and raw material sourcing.

"First off, I would like to say that it is a pleasure to work with you and Bill of the Titoma organization. You are prime examples of what it takes to make a company a world class end to end manufacturing organization that meets or exceeds needs of its customers. Hats off to you and your owners!"

"I am honored to testify as a satisfied customer. I'm very happy with the work you did during the manufacturing phase, and especially grateful for the attention you gave me during the whole process."

"We decided to work with Titoma because of their reputation and competitive price. We saved up to 100% higher on NRE (Non Recurring Expenses, i.e. design and molds) and 50% on parts. They delivered full turnkey development with impressive professionalism and quality. We have further products lined up for the coming year, and we will look forward to working with Titoma again."

"I recommend Titoma as an excellent partner for die-casted and injection molded parts. During the whole process we had very fast communication, and Titoma offered many useful suggestions on how to improve our mechanical design to avoid problems. The resulting parts were beautiful with a nice finish, and they managed to achieve the tight tolerances we required."

"We used to buy our custom made keyboards directly from a factory in Taiwan. Unfortunately, working with them turned out to be a major headache--endless shipping delays, which cost us a lot of customers. Two years ago, we asked Titoma to select and manage a new factory. Having a team on the ground that really understands quality and is able to make decisions on the spot saved us a lot of time and hassle."

"First off, I would like to say that it is a pleasure to work with you and Bill of the Titoma organization. You are prime examples of what it takes to make a company a world class end to end manufacturing organization that meets or exceeds needs of its customers. Hats off to you and your owners!"

"I am honored to testify as a satisfied customer. I'm very happy with the work you did during the manufacturing phase, and especially grateful for the attention you gave me during the whole process."

"We decided to work with Titoma because of their reputation and competitive price. We saved up to 100% higher on NRE (Non Recurring Expenses, i.e. design and molds) and 50% on parts. They delivered full turnkey development with impressive professionalism and quality. We have further products lined up for the coming year, and we will look forward to working with Titoma again."

"I recommend Titoma as an excellent partner for die-casted and injection molded parts. During the whole process we had very fast communication, and Titoma offered many useful suggestions on how to improve our mechanical design to avoid problems. The resulting parts were beautiful with a nice finish, and they managed to achieve the tight tolerances we required."

"We used to buy our custom made keyboards directly from a factory in Taiwan. Unfortunately, working with them turned out to be a major headache--endless shipping delays, which cost us a lot of customers. Two years ago, we asked Titoma to select and manage a new factory. Having a team on the ground that really understands quality and is able to make decisions on the spot saved us a lot of time and hassle."