What is a durometer?

The durometer is a measuring instrument dedicated to testing and measuring the hardness of different types of materials.

They’re able to perform hardness tests on

- Metals

- Plastics

- Rubbers

- Elastomer

The hardness of a material is defined as The resistance a material has to permanent penetration under some static or dynamic load.

How Does a Hardness Test Work?

Factors that Influence a Durometer Hardness Measurement Result

How deep the surface indentation can be will depend on

- The real hardness of the material of course

- The viscoelasticity of the materials

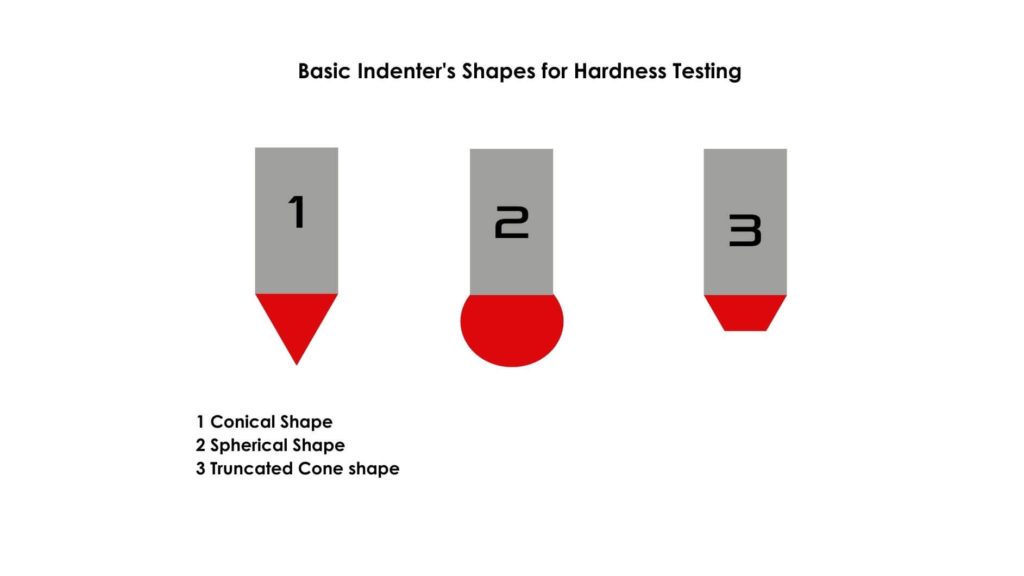

- The shape of the indenter

- The duration of the force applied to the surface

Basic Requirements for Accurate Hardness Testing

- Apply force in a consistent manner

- Avoid shock waves

- The material should be at least 0.25 inches thick

- Thickness exception may apply for extremely hard materials

- There must be sufficient material around the indenter, for softer materials a minimum of 6mm is recommended.

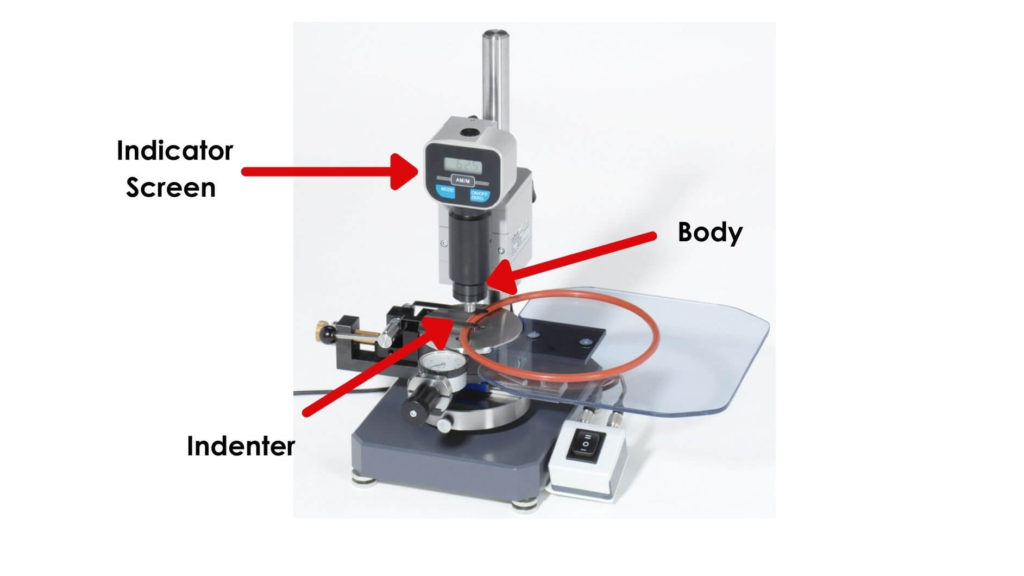

Parts of a Durometer

There are quite a few different types of durometers in the market and their shapes and parts might vary a bit making you feel a bit confused about what you need to focus on when looking to purchase one.

Well, don’t worry, this is what you have to pay attention to

Body: This is the part of the durometer that is in charge of generating the load that is exerted on the material. An accurate hardness measurement depends a lot on the well functioning of this part of the durometer. All loads have to be standardized.

Indenter: This is the part of the durometer in charge of making the indentation on the surface of the material.

Indicator screen: This will show the results of the test, the overall hardness measurements data

As its name says, it is responsible for indicating the hardness obtained during the measurement process. It will also instruct you on which type of indenter to use.

Types of Durometers

Shore Durometer

Its name comes from its inventor, Albert Shore.

Once the mark (indentation) is made on the material, the depth is transmitted to a spring in a dial gauge, which gives us the hardness value

Rockwell Durometer

This type of durometer is capable of measuring the hardness of any metal or alloy, both hard and soft. Its method of operation is to initially exert a small load, which increases the accuracy of the measurement and subsequently exerts a greater load.

Brinell Durometer

This durometer is used with a hard spherical indenter and uses constant load application, the diameter of the indentation is measured with a microscope and it is converted to a specific HB number using a formula.

Vickers Durometer

It focuses on observing the resistance of the material to the deformation. It’s considered a microhardness durometer. The resulting indentation is measured with a built-in microscope and transformed to HV or DPH hardness value using a formula.

These durometers incorporate a computerized image analyzer; it analyzes the location of the indentation, calculates the hardness values , and plots the information in a graph.

Knoop Durometer

This durometer is similar to a Vickers Durometer, the only difference is that a much smaller material sample is needed to run a material hardness test.

Leeb Durometer

This durometer leaves a smaller indentation than any of the other durometers in the list. Its operation is characterized by reading the energy loss that happens in an impact after hitting the material sample.

This means that this device generates an initial impact and after hitting the material, impact energy is lost and such loss is converted and measured in terms of hardness level.

Plastic Injection Molding

What is Plastic Injection Molding? It’s a manufacturing method used to make custom-molded parts, whether for consumer products or high-end B2B plastic products.

Durometer – 2 Minutes to Know What It Is and How to use it

What is a durometer? The durometer is a measuring instrument dedicated to testing and measuring the hardness of different types of materials. They’re

Pipe Size Chart

The Latest Pipe Size Chart Pipes are used in mechanical engineering across different industries. Pipes are hollow; this means they have an outer diameter and